- We are sure we can support cost reduction of your company.

- We are sure we can support commercialization of your products.

- We are sure we can support manufacturing in your company.

What is Sharing Service?

While manufacturers specializing in traditional manufacturing are gradually decreasing in Japan, those specializing in IoT and other planning and application software are increasing. With its long history, TKR has expertise in all operations related to development, hardware design, and manufacturing, as well as those related to warehousing, support, and repair that are required after sales. We can support commercialization of customers’ products.

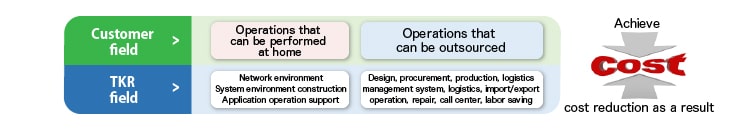

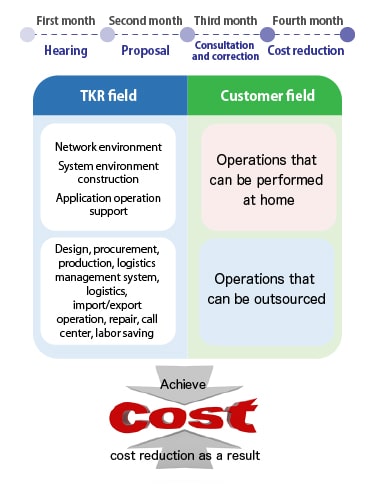

Under the current situation where it is difficult to secure profits in Japan, TKR provides a service called Sharing Service, which enables you to reduce personnel and other expenses by nearly half by entrusting a part of your normal operations to TKR.

7 contents of Sharing Service

TKR Japan will be in charge of communication with customers, and overseas staff will carry out back-end work. This enables low labor rate and labor costs. Customers are not affected by the principle of equal pay for equal work.

Since customers can use the processes, databases, and infrastructure of TKR, little initial cost is required.

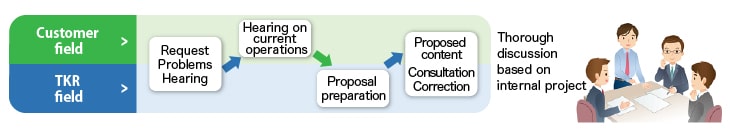

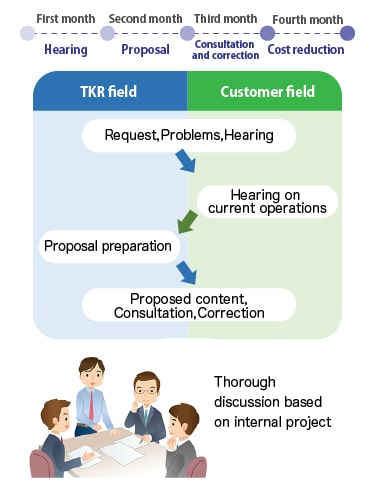

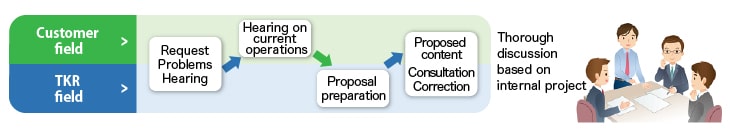

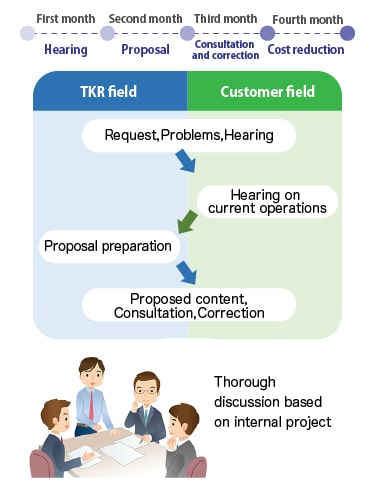

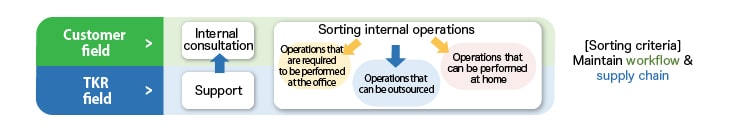

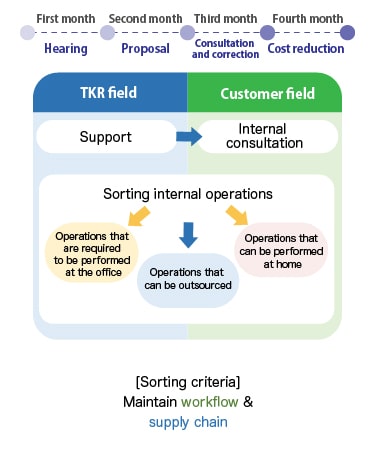

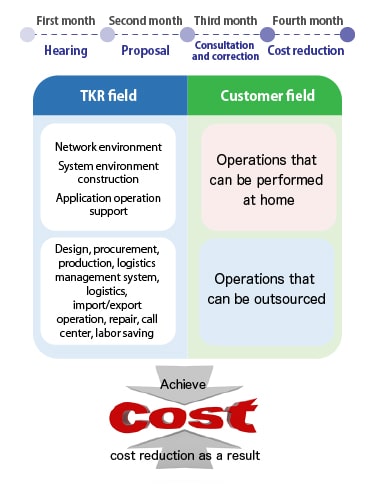

Process for improving internal operations

*Schedule image: We will discuss the actual schedule separately after the first hearing.

Phase 1: Current state analysis

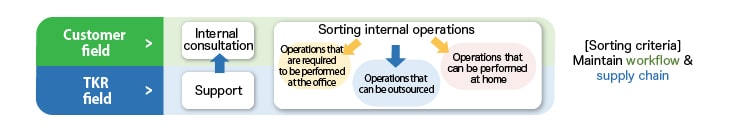

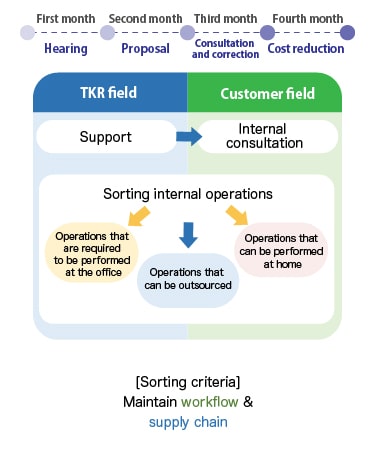

Phase 2: Sorting internal operations

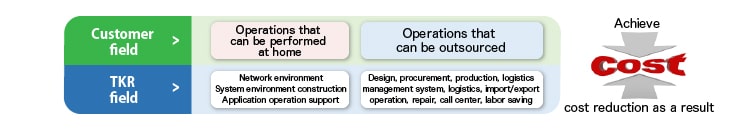

Phase 3: Shift to operation reduction

Expected effects

Reducing internal operations

- Optimize

personnel deployment by operation sorting

- Improve operational efficiency

Reduce overtime hours

- Solve a manpower shortage

Utilize outsourcing

[Example of TKR's work style reform]

2017: Launched a project to improve operational efficiency by 5% annually

Achieved the goal and continue to implement the project

2020: Realized that 80% of the employees work at home due to COVID-19 outbreak

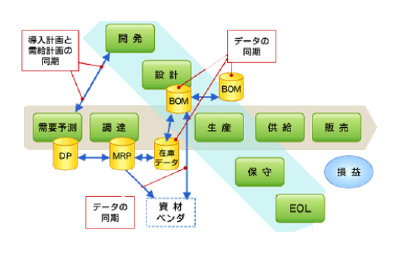

Maintaining a stable supply chain

- Make full use of the TKR Group's network

- Provide alternative supplies in response to disasters in specific areas

- Sustain and strengthen the supply chain

[TKR's emergency response]

2003: The SARS outbreak in China

2011: The Great East Japan Earthquake

2011: Flood damage in Thailand

In response to a request from a major home appliance manufacturer, TKR provided emergency contract production services.

Reducing procurement and materials costs

- Negotiate procurement management costs,

prices, and delivery dates

- Reduce mold costs for in-house manufacture of mechanical components

- Realize optimal purchasing and optimal pricing

[Procurement management of the TKR Group]

By using an in-house developed system, each plant manages the unit price of parts purchased

Same unit price for the same parts

Implement and operate optimal purchasing

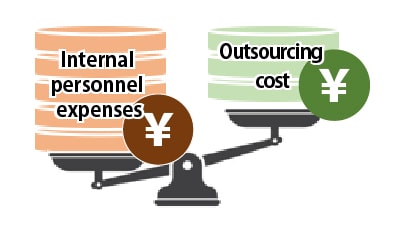

Reducing total cost

- Internal personnel expenses

8.6 million yen per year per person

Converted to sales: 84 million yen per year

- TKR’s cost structure

[Statistics by the Ministry of Economy, Trade and Industry]

Manufacturing industry statistics for FY2017

Average personnel expenses: 8,596,900 yen

Labor share: 46.1%

Value added: 22.1%

Sales per person: 84.38 million yen

For inquiries about Sharing Service, please click “Contact Us” below.